Mechanical engineering from a single source

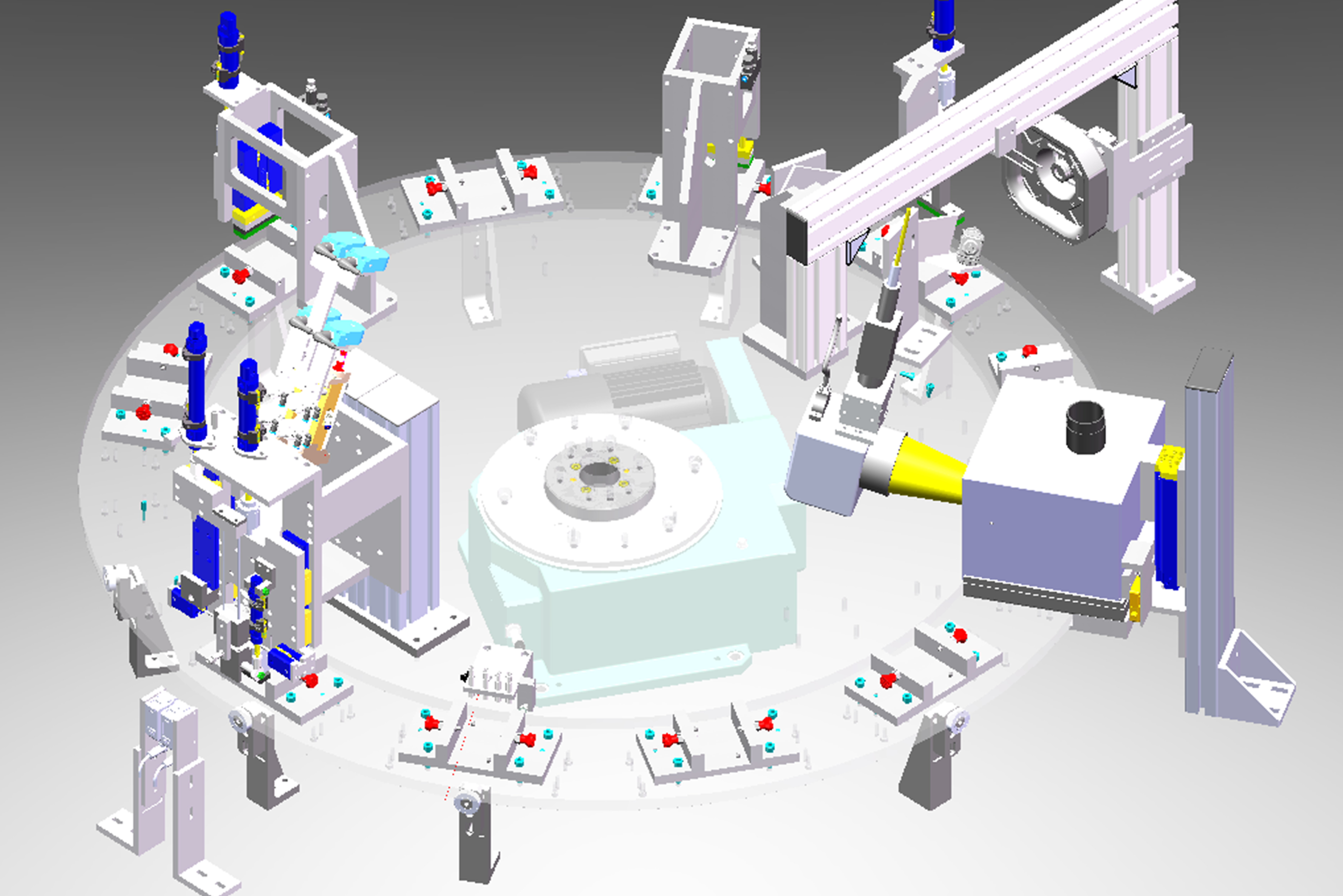

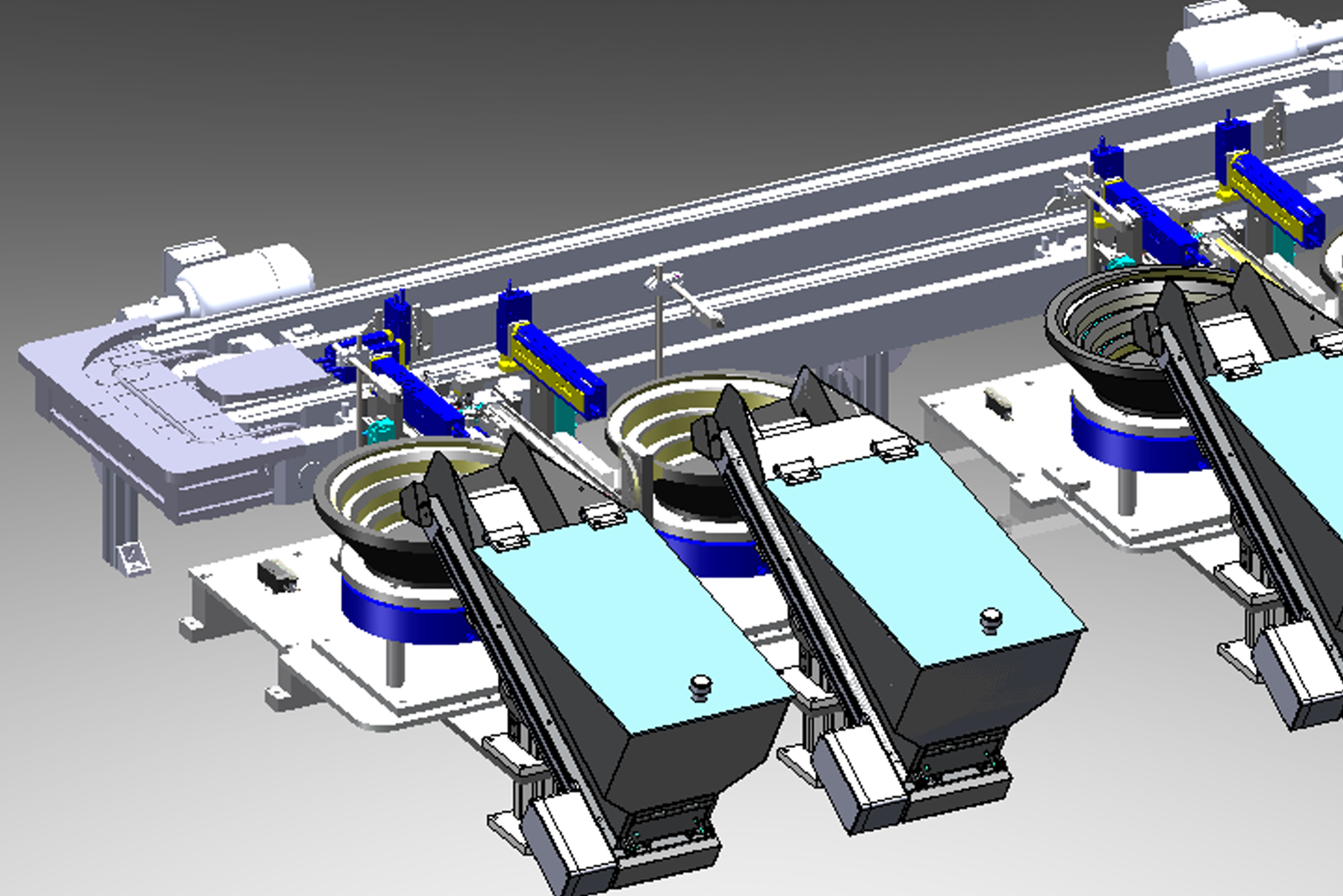

Production lines & rotary transfer machines

Information, details, descriptions

Our production lines and rotary transfer machines work highly efficiently and reliably for numerous applications and processing variants.

We use rotary transfer tables from 2 to 30 positions, 6-axis robots and pallet circulation systems. We are happy to realise this and much more for you. Using our machines, we produce in one, two and three-shift operation.

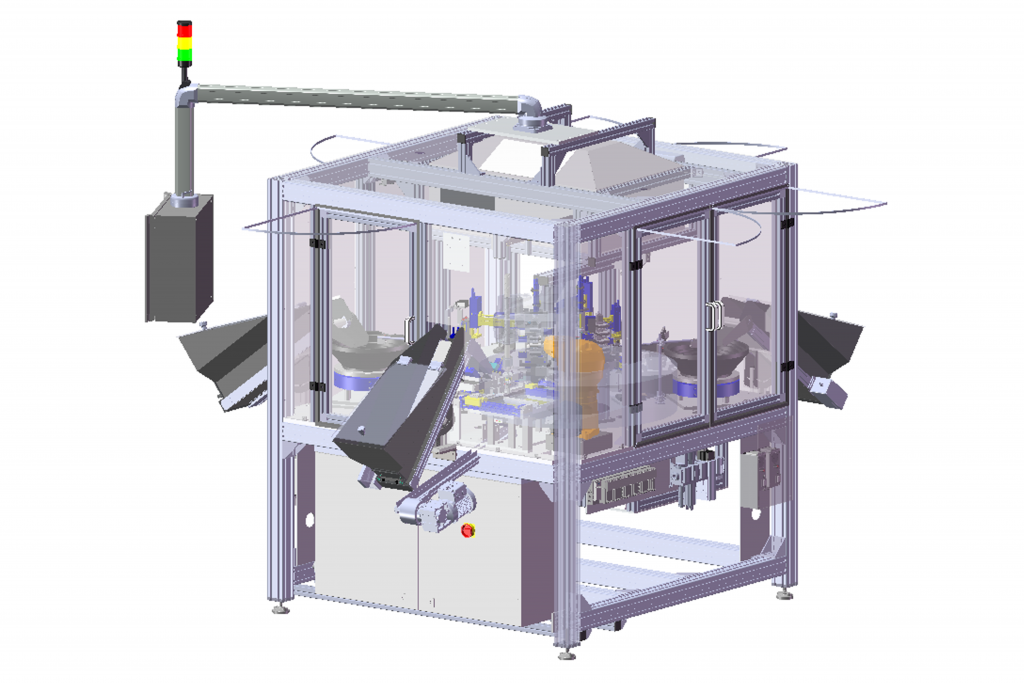

Fully automatic assembly systems

- Fully automatic assembly systems (for example for the production of headrests) with automatic feeding, process several variants of retaining bar brackets, two variants of head boxes and coiled spring pins. Loading and unloading the turntable takes place by robot. Pneumatic actuators are responsible for mounting the retaining bar brackets in the head boxes and securing them with coiled spring pins. A camera inspection with good part marking by laser completes the process.

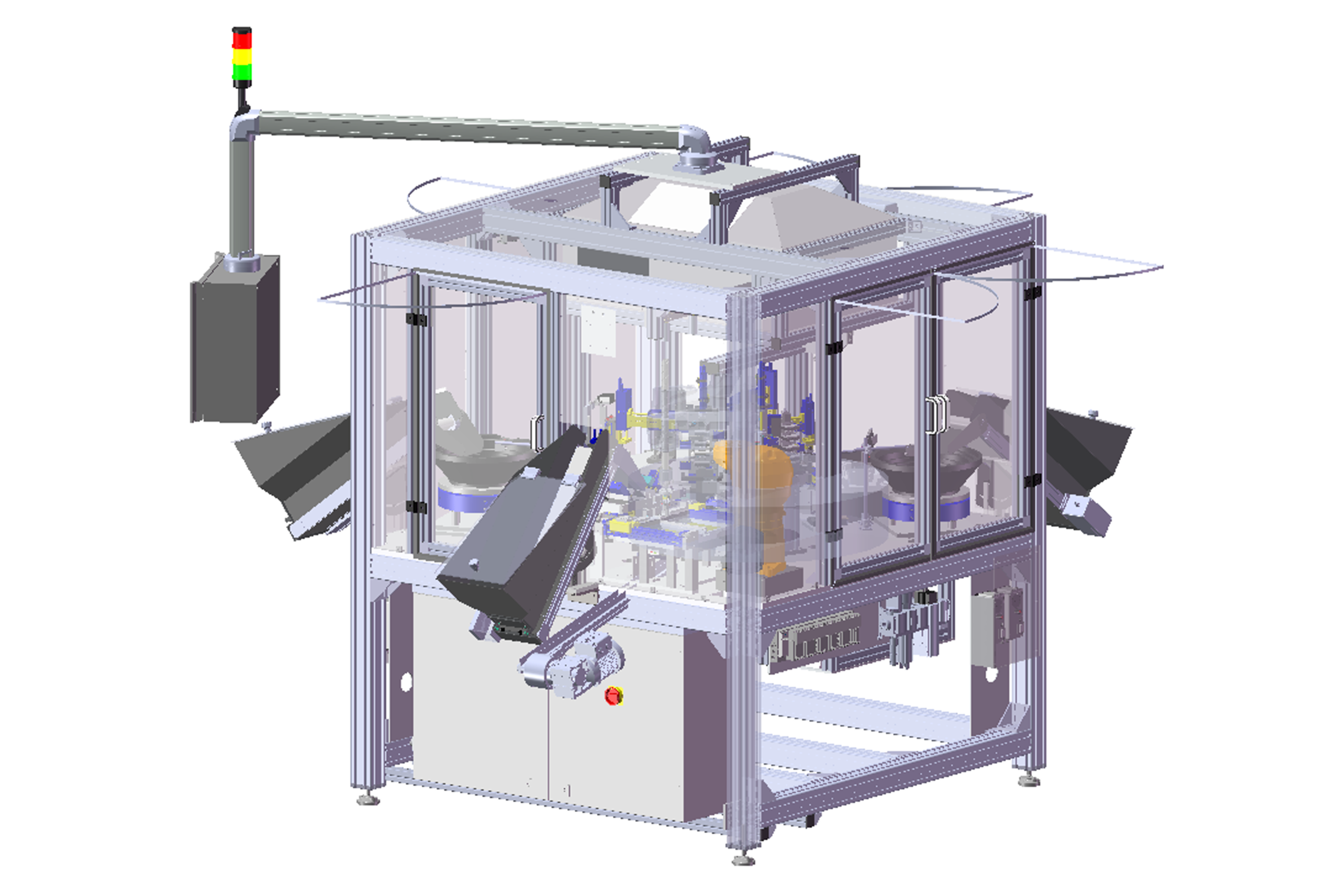

Rotary indexing assembly machines

- We create rotary indexing assembly machines for the production of cosmetic articles with high cleanliness requirements, and more besides. Automatic feeders serve to separate the individual components in the correct position before they are inserted into the designated assembly nests on the rotary indexing table using a pick-and-place system, ionized, joined step by step and and tested. Good and bad parts are placed in separate containers. A flow box prevents dirt particles from entering the machine.

Fully automatic punching

- We offer our production lines for the fully automatic punching of 24-, 32-, 54- and 64-pole connectors, as well as different colored connectors in a range of versions. Stocking takes place by means of ergonomically fillable inclined conveyors, which fill spiral conveyors manufactured by us. Gripping and setting units load the workpiece carriers on the pallet circulation system with the separated connectors. The flexible, rapide and accurate punch units also impress with freely selectable punch patterns. Blow-off units remove punching waste and image processing systems check the connectors.

Have you not found the perfect match for you here?

Then just ask. Our experienced staff are certain to have an idea and an approach that will satisfy your requirements.