Technology that sets us apart

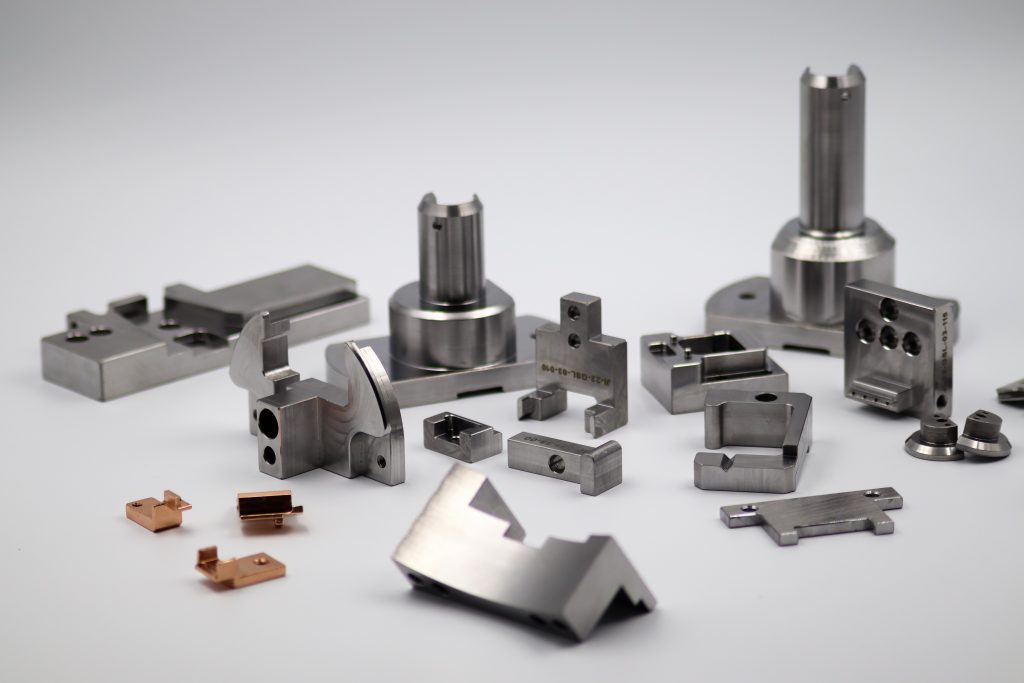

CNC Production

Thanks to precise machining with extensive precision tools and finishing with skilled craftsmanship and reliable partners, our customers enjoy a wide range of part production options with the major advantage of obtaining everything from a single source.

- DMG-50 5 axis x 500mm, y 450mm, z 400mm

- DMG-70 eVolution 5-axis simultaneous x 750mm, y 600mm, z 520mm

- DMG-75 monoBlock 5-axis simultaneous x 750mm, y 650mm, z 550mm

- DMV 115 3-axis x 1,150mm, y 700mm, z 550mm

- Mastercam

Capable of machining steel, low-alloy or high-alloy, non-ferrous and light metals as well as many kinds of plastics. We keep many of these in stock.

Burnishing, nitriding, hardening, annealing, electroless nickel plating, phosphating, hard and color anodizing, galvanizing, painting, powder coating, sandblasting, polishing, flocking or blank. We offer these and even more surface treatment options.

Our regional suppliers quickly and reliably supply us with the machining techniques including surface and cylindrical grinding, wire cutting, eroding, water jet cutting, laser and laser bent-parts, flame-cut parts, raw materials and much more.

Our conventional milling, turning and grinding machines support and complement this broad palette.

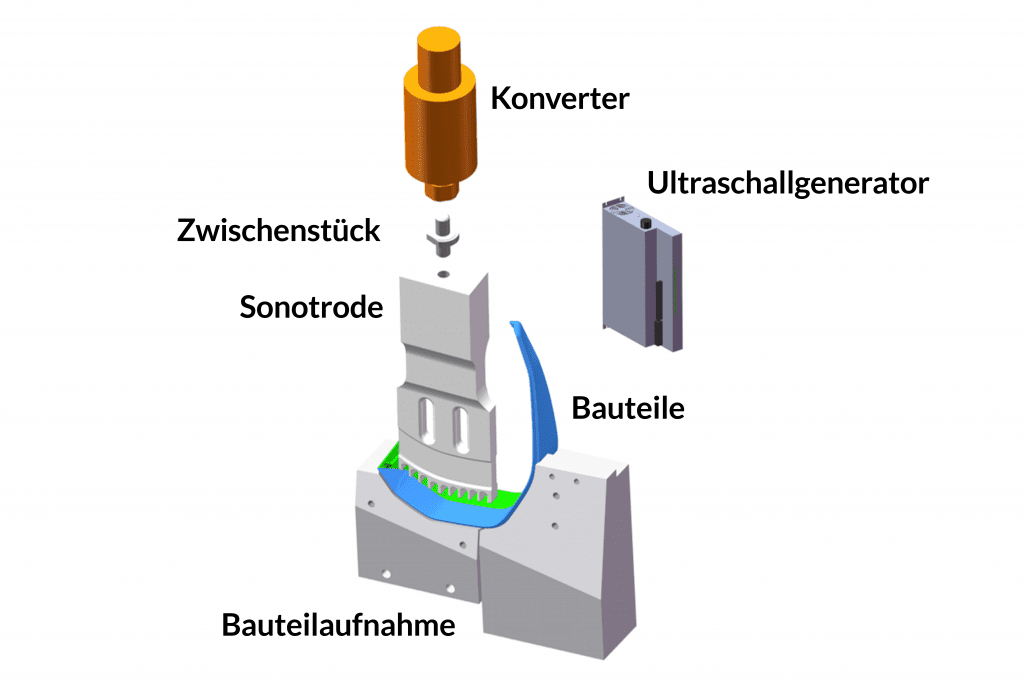

Ultrasonic welding

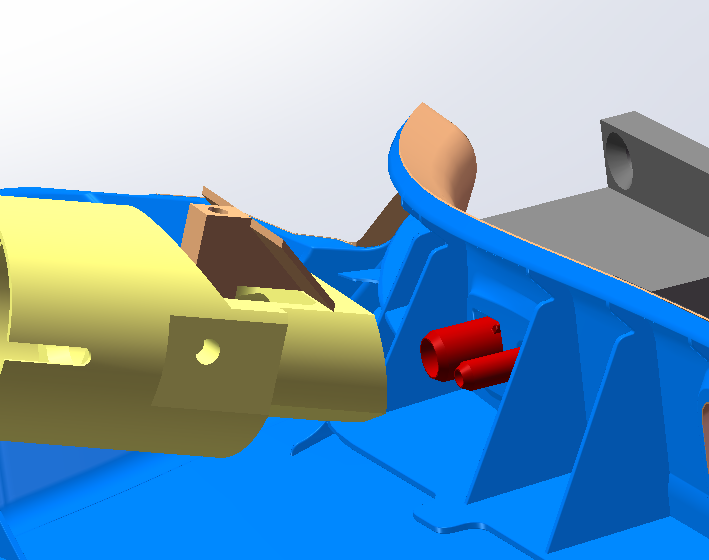

Our expertise lies in the production of sonotrodes, sonotrode carriers and holders.

We realise customer-specific tool shapes and application areas with 3D-CAD and our CNC-CAM production and perform the adjustments with the absolute precision required. We offer you everything from a single source – meaning that we can offer highly complex geometries and very short delivery times.

We manufacture these from aluminium, titanium or tool steel.

Properties and advantages of ultrasonic welding:

- In pulsed ultrasonic welding, one or more thermoplastic materials (e.g. PP, PVC, PE, PET,

- ABS, composites, fabrics, nonwovens or films) are joined together by internal friction in the joining zone.

- Precise control technology ensures accurate, consistent and reproducible quality.Cost-effective and environmentally friendly technology with low energy requirements and without the use of solvents.

- Rapid process times, no waiting times for heating up and cooling down the tools.No risk of injury from hot machine parts.

- Almost no heat input into the component due to the cold welding tools.Energy savings are realised thanks to short welding times.

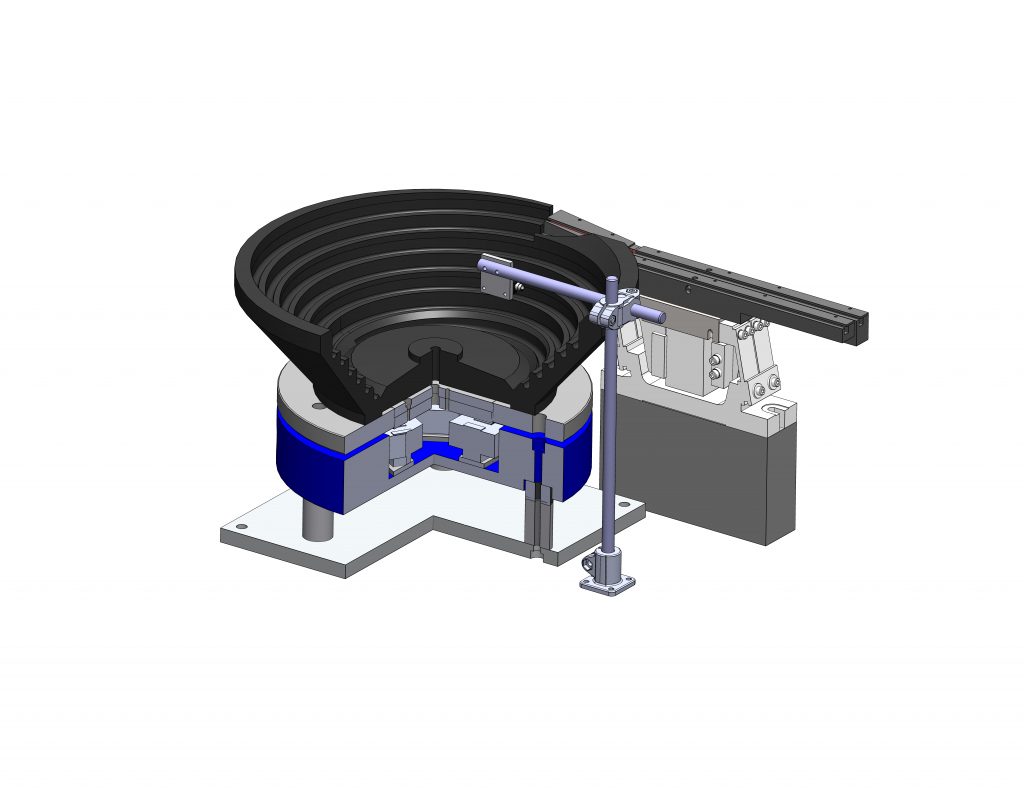

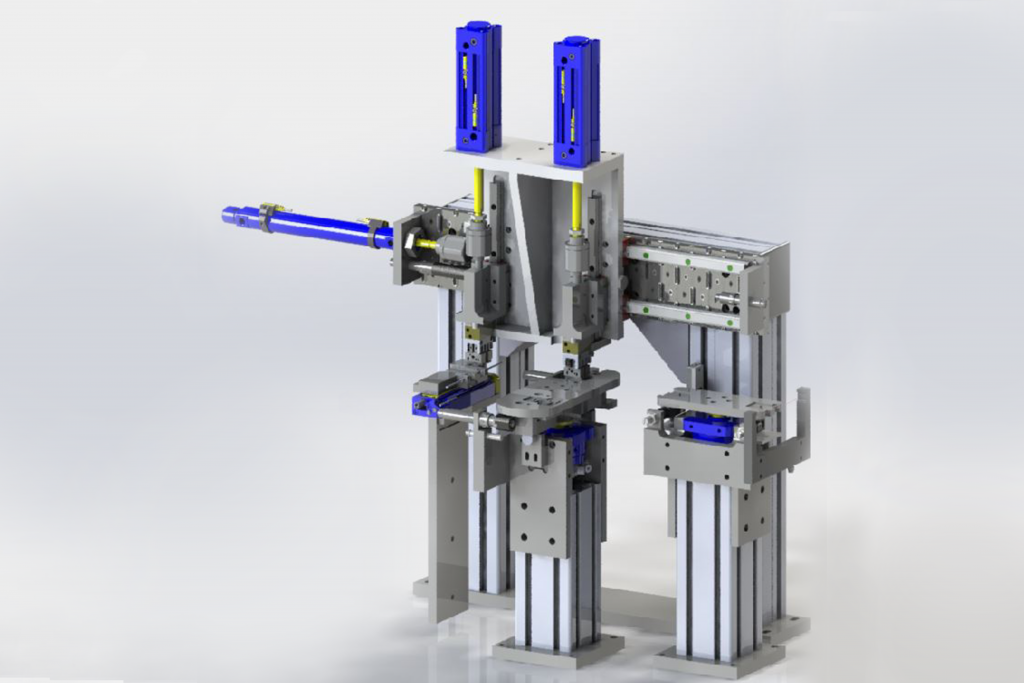

Feeding and separation systems

Our expertise lies in the manufacture of feeder bowls with sorting sections, drivers, linear sections, testing and transferring units.

We realise customer-specific applications with 3D-CAD and our CNC-CAM production.

We fully manufacture the drives for the spiral conveyors in the standard sizes 250mm and 30mm.

We manufacture our standard PA spiral conveyors in the standard sizes 200mm to 500mm. Special solutions such as steep wall designs are also possible.

The advantages of PA spiral conveyors include their very smooth running, their straightforward adaption to change conditions, and the responsibility of reproduction with repeat accuracy for spare parts requirements.

We carry out complete production I-house – meaning that we can offer feeders for a wide range of parts with very short delivery times.

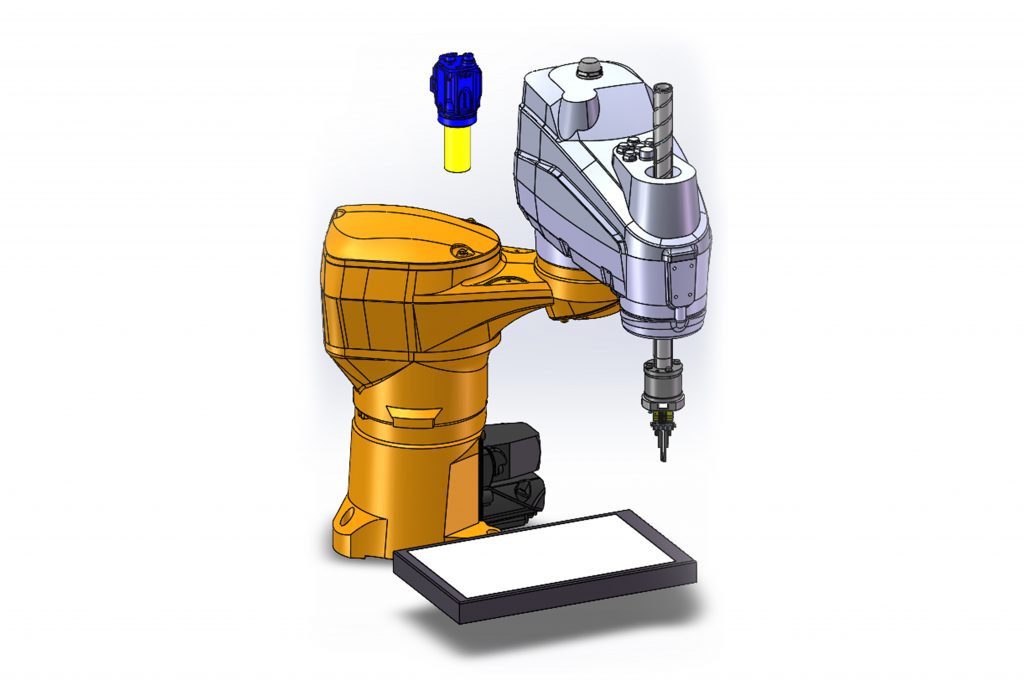

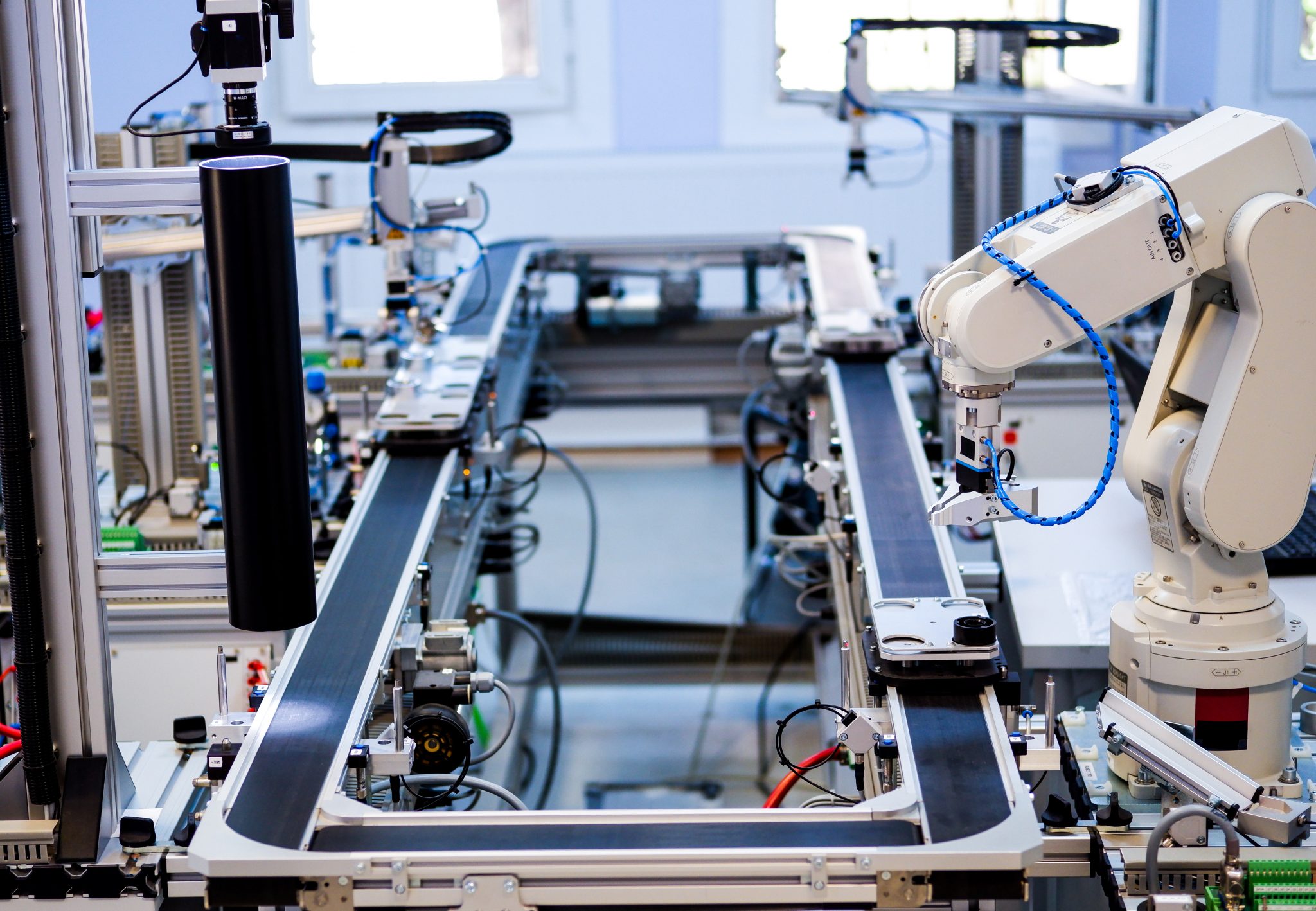

Robotics

At SUSO, we provide you with a tailored solutions in the field of robotics. In order to deliver your customised automation, we manufacture robot systems that are suitable for flexible and universal use as complete solutions. Working in combination with a 2D or 3D Camera system, we are also able to handle complex parts safely and reliably. We work with a range of suppliers and are happy to create to the wishes of our customers.

CAD design

Very short, internal communication and coordination channels, as well as direct contact with our customers, allow us to take care of tasks rapidly and at short notice, which considerably speed up delivery times.

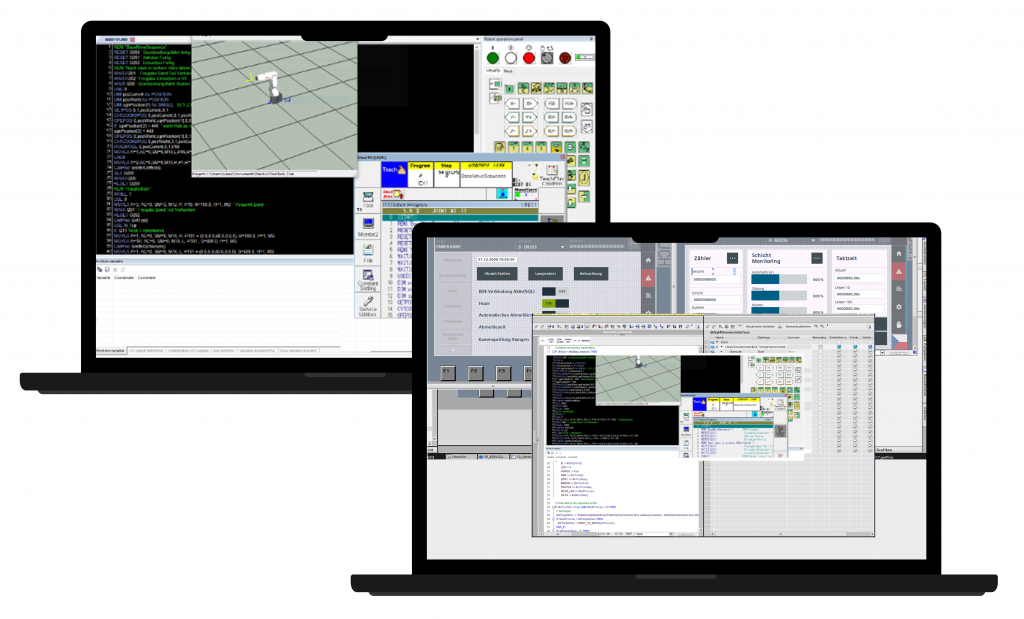

PLC programming

In automation, we use controls from Siemens, for example TIA (Totally Integrated Automation), WinCC (Windows Control Center), Step 7 classic, Step5 or Beckhoff TwinCat. On consumer request, we also create automation solutions based on other providers. We use bus systems such as Fieldbus, IO-Link, Profinet, Profibus, ASI, Ethercat, etc. are used. The drive technologies from Siemens, Festo, SEW, Beckhoff and many more, as well as HNC hydraulic components from Bosch Rexroth.

Technical documentation

We also prepare the technical documentation for our machines in-house. Performing the conformity assessment in accordance with the applicable Machinery Directive and verification of and compliance with all safety requirements are part of this scope. Depending on requirements, we also supply the operating instructions with EU/EC Declaration of Incorporation.

This includes:

Technical data

Safety instructions

Fault description

Maintenance and servicing instructions

Overview drawing with parts list for spare parts procurement

Electrical circuit diagram with test report according to DIN VDE 0113 /EN 60204

Pneumatic diagram with parts list

Replacement and wear parts list

If applicable, machine capability

If applicable, follow-up time measurement with report EN/ISO 13855:2010

Parts documentation in the languages of the manufacturers

Hot stamping and hot caulking

Hot air stamping:

Form-fittting connections are establishes by hot air stamping. The connection is realised forming the thermoplastic. This process allows us to produce point or segment-like joints.

Heat caulking:

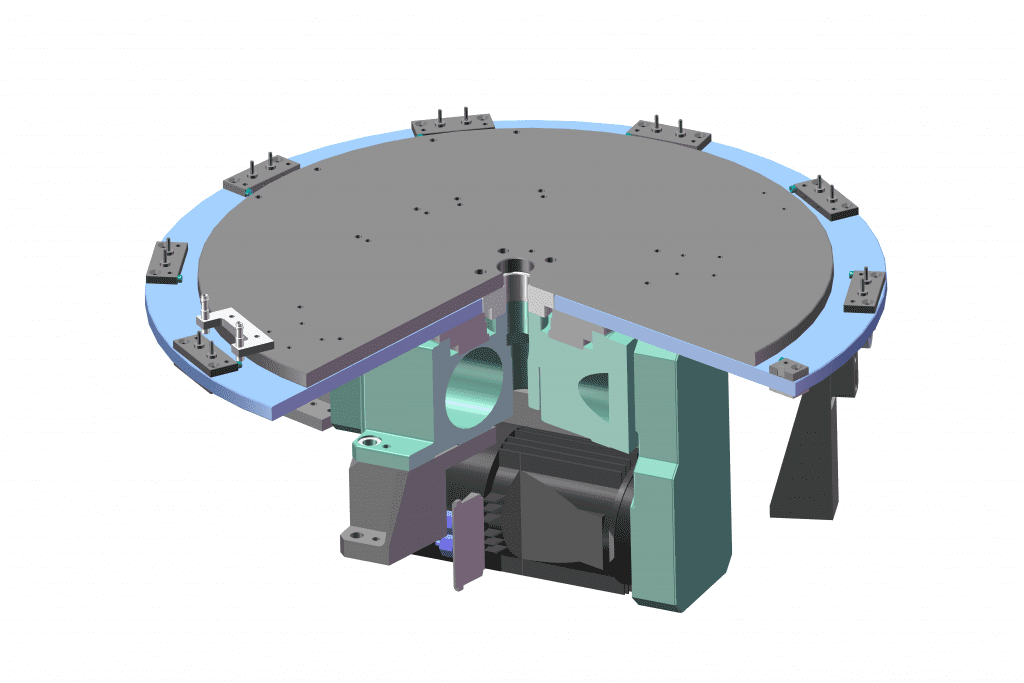

Rotary indexing tables

This technology is used in our rotary transfer machines. As a single cycle system or paired with other systems in order to combine different work steps.

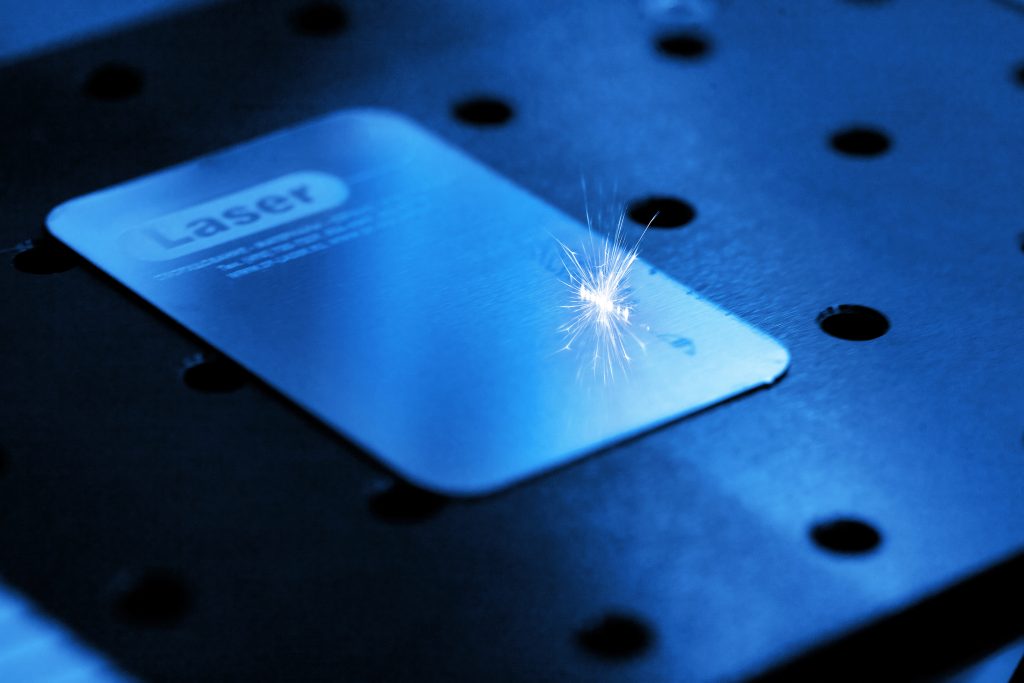

Laser units

We have set ourselves the task of responding quickly and independently and assemble individual laser components into a laser unit, which we also commission. Many parts that our machines produce can be marked, identified and labelled in this way. This allows us to realise QR codes, barcodes, batch numbers or type designations.

Workpiece carrier circulation and linear system

Gripping and handling components

Marking and labeling technology

We apply the marking and labeling technology directly on the component or on the packaging. The labeling takes place according to the requirements of the components, traceability and materials. Serial and batch number, barcode, QR code or date of manufacture and much more. we apply, among other things, needle embossing, labels, stamps, pad printing, inkjet, etc.

Other technology

our impressively wide-ranging special machine and prototype construction with countless possibilities leaves little to be desired.

We install almost all systems available on the market.

Force-displacement measuring systems

Screw systems

Vision sensor systems

Camera systems

Robot changing system

Testing systems

Scanning systems

Lubrication systems

Hydraulic systems

Counting systems

Sorting systems

Belt systems

Storage systems

Heating and cooling systems

Cutting and separating systems