Mechanical engineering from a single source

Semi-automatic assembly & testing machines

Information, details, descriptions

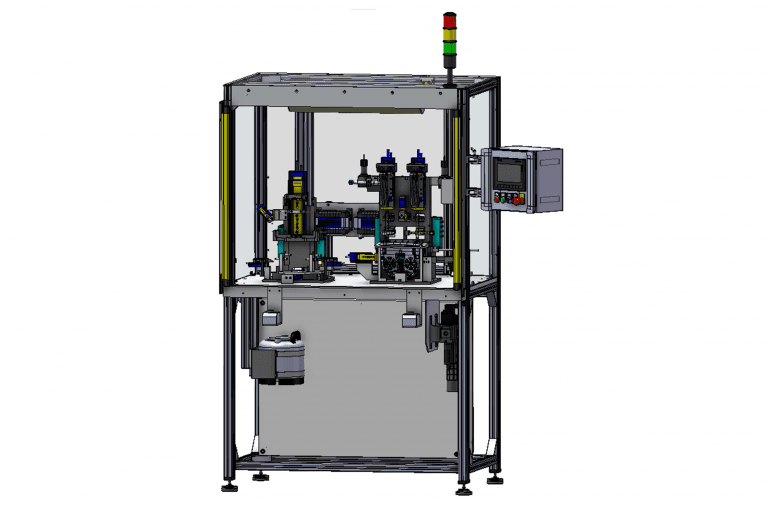

Machines of this type are used where smaller quantities are required. They also serve as a back-up for production with delicate processes or where supply chains need to be secured. Small parts with larger quantities are fed by machine. The assembly or joining and testing processes take place automatically. The products can be removed by the worker or handling systems. Appropriate safety devices ensure extremely safe operation of the systems

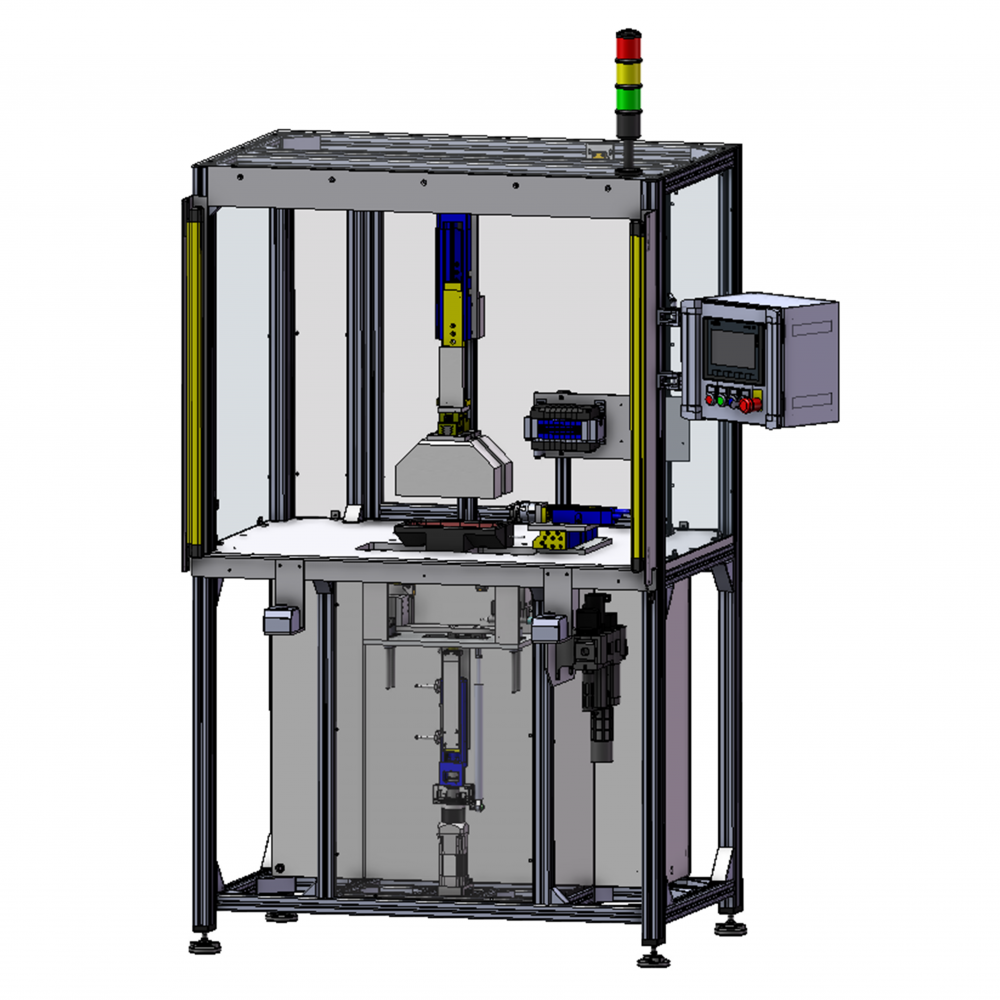

Semi-automatic assembly machines

- Semi-automatic assembly machines are ergonomically designed – also for user by people with a disability, e.g. for life-support facilities. Using these systems, the worker loads and removes bulky base bodies. Parts in larger units quantities are automatically fed, insert and remove again.

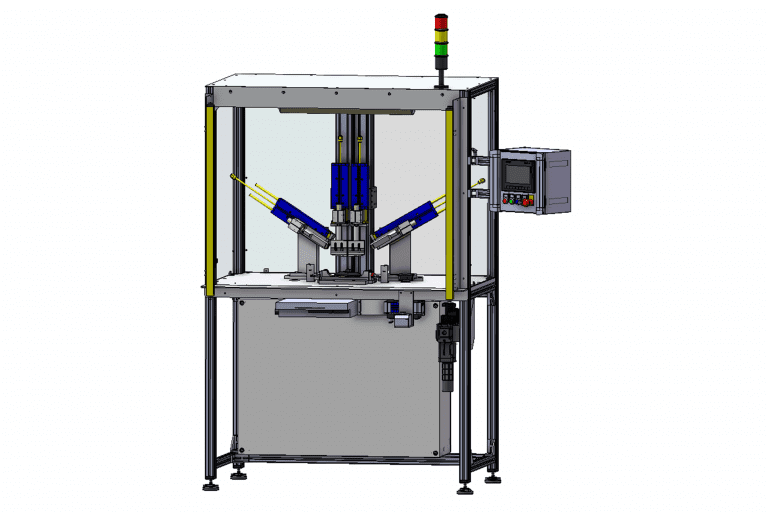

Semi-automatic test systems

- Semi-automatic rotary transfer testing machines for cast aluminium lids. Loading and removal are carried out by the worker, in each case after rotation of the rotary indexing table. A transfer handling system places the lid on a specially shaped and sealed testing nest. A pressure test decides on the quality and the resulting, respective inscription by means of a needle embosser. Bad parts are sorted out, good parts are removed by the worker.

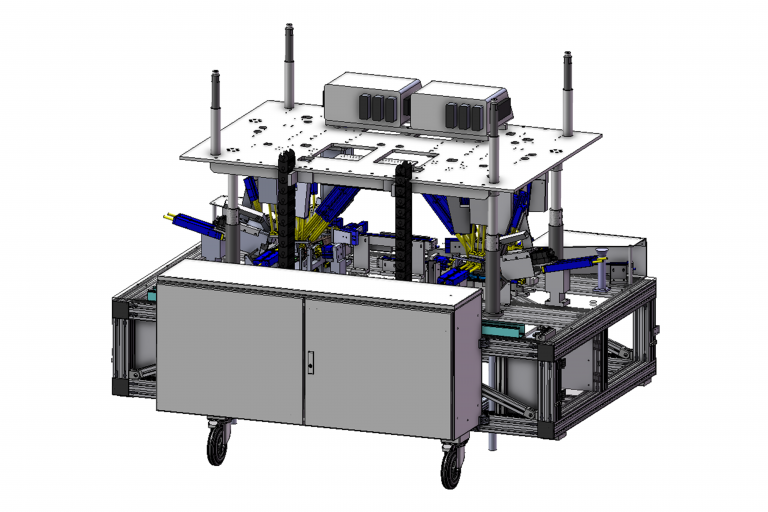

Semi-automatic tool trolleys

- Semi-automatic tool trolley for ultrasonic welding of plastic parts and fabric covers in vehicle interiors. Bulky parts are inserted manually into specially coated mold nests and joined by means of ultrasonic welding units. Mold nests and ultrasonic sonotrodes are manufactured, tuned and commissioned by us.

Have you not found the perfect match for you here?

Then just ask. Our experienced staff are certain to have an idea and an approach that will satisfy your requirements.